| Company Details | |

|---|---|

| Company Name | The Good Plastic Company |

| Company Address | Keersluisweg 7, Hal 1 Almere 1332 EE Netherlands Map It |

| Your Contact Details | |

| Name | Alisa Mitlitska |

| Job Title | Marketing Manager |

| Email hidden; Javascript is required. | |

| Phone | +34610651067 |

| Role of this organisation in the project being entered | Material Producer |

| Category - Interior |

|

| Entry Details | |

| Name of organisation entering the Awards (if different from above) | The Good Plastic Company |

| Role of this organisation in the project being entered (if different from above) | Material Producer |

| Project/Product Name (written how it should appear) | Polygood® |

| Project Address | Keersluisweg 7, Hal 1 Almere 1332 EE Netherlands Map It |

| Client Name | Alisa Mitlitska |

| Designer/Architect Name | - - |

| Contractor Name | - - |

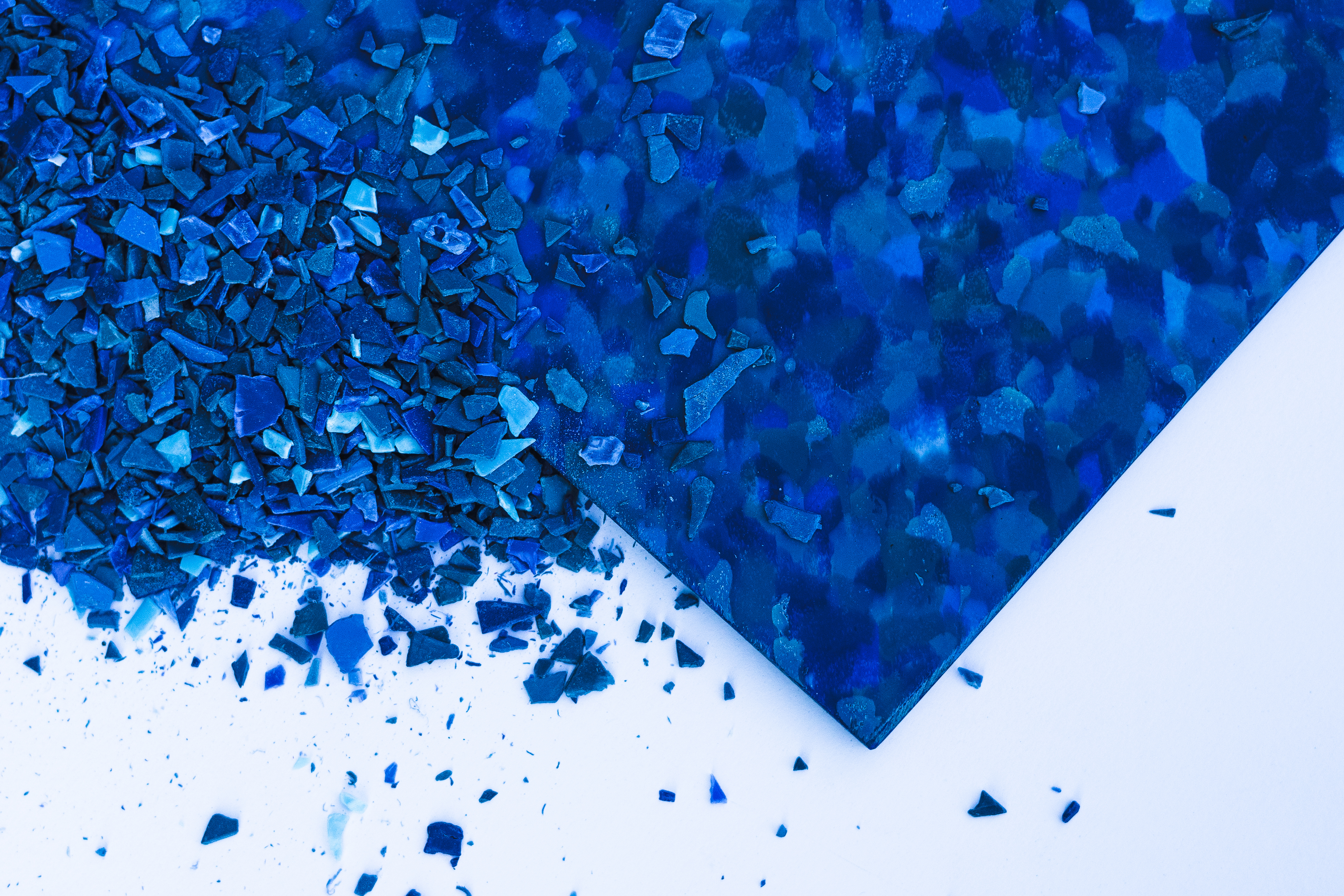

| Project/Product Description | Polygood® from The Good Plastic Company is a solid surface material produced entirely from 100% recycled and recyclable plastic, offering an unparalleled sustainable and practical choice. The product’s diverse patterns have a distinctive visual allure and can each be produced consistently over time and in large volumes due to a robust supply chain. This choice of material helps divert plastic away from incinerators, landfill, and the natural environment, and delivers the maximum benefit from precious resources by reusing them through the company’s take-back and remanufacturing programme, according to circular manufacturing principles. The product stands as a distinctive, large-scale offering compared with more artisanally produced alternative sustainable materials, giving clients the opportunity to make significant positive environmental impact. Key points: - Industrial volumes: we can supply projects requiring hundreds of square metres of material Polygood® is available in a category-leading wide range of patterns suiting every design context, from ones mimicking the colours and textures of natural stone to others that are brightly coloured and that make a virtue out of being obviously plastic in origin. Polygood® is a pioneer not just because of the material’s environmental credentials but because of its remarkable versatility and adaptability, able to meet the requirements of applications across diverse market segments. Key Market Segments and Applications: 1. Retail: point of sale/plinths, retail counters, exhibition booths, signage. Some representative projects where Polygood® is used include: 1. Exterior cladding of the UK’s first Net Zero Carbon McDonald’s restaurant at Market Drayton Other clients include Nike, Adidas, Coach, Karl Lagerfeld, Harvey Nichols, Selfridges, HSBC, Mercedes-Benz, Samsung, Spaces, and MVRDV. Workability: 1. Polygood® panels can be cut with woodworking tools, CNC machines or water-jet. |

| Materials Used | We have chosen to make Polygood® from polystyrene (PS), a durable and resilient type of plastic that provides excellent structural integrity and that also minimises resource usage and emissions in the recycling and manufacturing processes, aligning with eco-friendly principles. Its mechanical and aesthetic properties suit Polygood® to both structural and decorative applications. The Good Plastic Copany partners with large recycling centres all over Europe that collect and sort plastics to ensure a reliable and high quality supply of material. They work both with post-consumer and post-industrial plastics. We and our suppliers have audited procedures to ensure that we can guarantee the composition of our products to our clients. Because our suppliers are large-scale recyclers, we have the ability to produce our products consistently over time and in high volumes. What distinguishes Polygood® is its extraordinary range of character, with each pattern originating from a combination of distinct waste sources, contributing to their unique back stories. The patterns stem from a wide range of post-consumer and post-industrial plastic waste streams, including sources such as refrigerators, single-use cutlery, household appliances, and manufacturing components. The wide range of distinctive designs suits every design context, from ones mimicking the colours and textures of natural stone to others that are brightly coloured and that make a virtue out of being obviously plastic in origin. |

| Sustainability | Polygood® holds Cradle to Cradle® certification, which puts it at the forefront of the sustainable surface materials segment, offering architects, designers, and brands a trusted solution backed by rigorous analysis, audit, and testing. Polygood® is the only plastic surface material to achieve this certification, solidifying The Good Plastic Company’s position as an industry leader in sustainable materials. Polygood® was also granted the first verified Environmental Product Declaration (EPD) for a plastic solid surface material. An EPD includes the assessment of a product’s environmental characteristics throughout its entire lifecycle. It covers the entire value chain, from material extraction to production, product use, and end-of-life disposal. In addition to supporting a circular economy, The Good Plastic Company offers a Take-Back Programme for Polygood® panels. Recycling old panels and offcuts allows the company to reduce the carbon footprint and limit our environmental impact, as recycling materials demands less energy than manufacturing products from raw materials. This programme fosters a closed-loop economy focused on reusing materials instead of creating new waste. CO2 information: The production of Polygood® panels not only avoids CO2 emissions but actively reduces them compared to the production of new plastic from virgin feedstock. |

| Supporting Images |